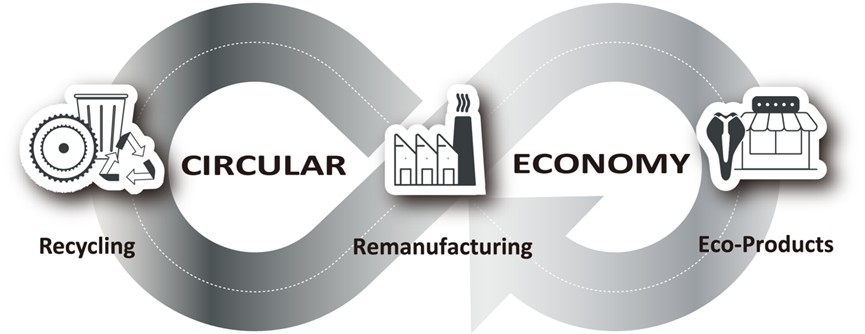

As global environmental awareness rises, “circular economy” has become a key trend in industry development. Velo, a pioneer in sustainable design, has long been committed to resource reutilization, focusing on integrating circular economy practices at both internal and external levels. Internally, Velo emphasizes recycling, reusing, reducing waste, and redesigning, optimizing everything from material selection to production processes to minimize environmental impact.

In this context, Velo has partnered with SRAM, a globally renowned bicycle component brand, to implement the circular economy. SRAM’s ZIPP brand, known for producing high-performance carbon fiber components such as wheels, handlebars, stems, and seat posts, has been highly praised in the market. However, the issue of how to recycle the leftover carbon fiber material from the production process and retain its value has long been overlooked. While SRAM has developed a comprehensive carbon fiber recycling system, the challenge remains how to maximize the reuse of these materials, which is where this collaboration becomes essential.

With over 45 years of experience in the bicycle industry, Velo manufactures 12 million saddles annually and is actively exploring alternative materials to reduce carbon emissions. Through this collaboration, the two companies successfully combined recycled carbon fiber waste with nylon to create a high-performance bicycle saddle material, ensuring that the carbon fiber waste, which would otherwise lose its value, retains equal worth.

Additionally, with Velo and SRAM’s factories located less than 20 kilometers apart, the supply chain process and transportation costs have been significantly reduced, further lowering the carbon footprint of the product. This new material has passed Velo’s rigorous laboratory testing and verification, ensuring it meets production and performance requirements. It has now been successfully applied to high-end saddles.