With heavy e-bikes surging in popularity, the market is demanding longer-lasting and sturdier fenders. As the leaders in plastic fenders, customers have long been seeking SKS’s latest offerings in this area.

“With heavier bikes, cutting fender weight is less of a concern. A plastic fender set can weigh 250 g, and aluminum 500 g. Even though our plastic fenders are reliably strong, aluminum is just stronger and will last as long as the bicycle itself,” said Stefano Zugno, SKS Export Manager.

A Closer Look At The EXO

Many people have already been interested in SKS’s latest EXO extruded alloy fender. Its side parts and accessories are plastic, but it’s now “super sturdy” with more integration compared to competitors—which is proving “very important” to factories.

The EXO took center stage at Taichung Bike Week (Pic: Ash Suter)

The EXO took center stage at Taichung Bike Week (Pic: Ash Suter)

The name EXO is derived from its exoskeleton—a structure that provides stability and protection. The newly patented EXO profile, with its innovative URS rail system, “meets the increasing demand for modern e-bike and city bike models,” “combining functionality and design.”

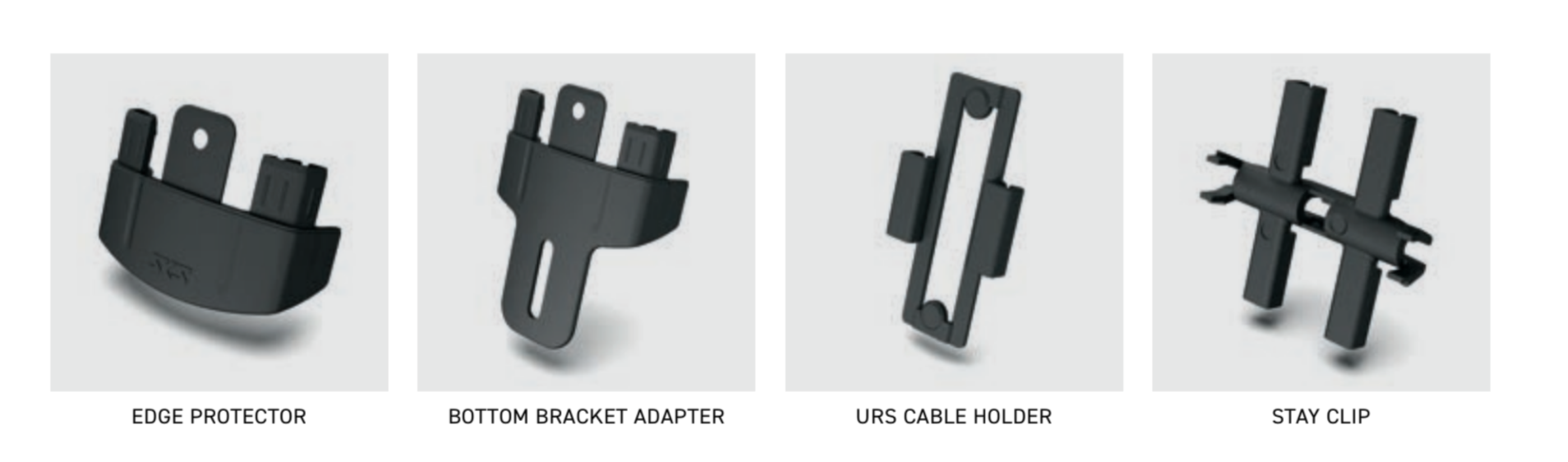

The URS rails on the underside provide variations in cable management thanks to the flexible cable clips that can be mounted. The URS stay clips, easy to insert and tool-free, will not be visible from the top, allowing for multiple clips and stays to be added. With the pluggable end cap, the edge will appear seamless and clean. They will be available for wheels with a radius of 20" to 29" and widths of 55/60/65/70/75/80 mm.

The rails are 4.5mm wide, but SKS are set to introduce 10mm in the future. (Credit: SKS)

The rails are 4.5mm wide, but SKS are set to introduce 10mm in the future. (Credit: SKS)

SKS believes there’s lots of flexibility due to their range of modular parts. (Credit: SKS)

SKS believes there’s lots of flexibility due to their range of modular parts. (Credit: SKS)

Here is the EXO with the pluggable end cap attached. (Pic: Ash Suter)

On both sides of the profile are fully closed hollow chambers providing stability and balance. The torsionally rigid structure remains so even with wide mudguards and long versions, says SKS.

Credit: SKS

Credit: SKS

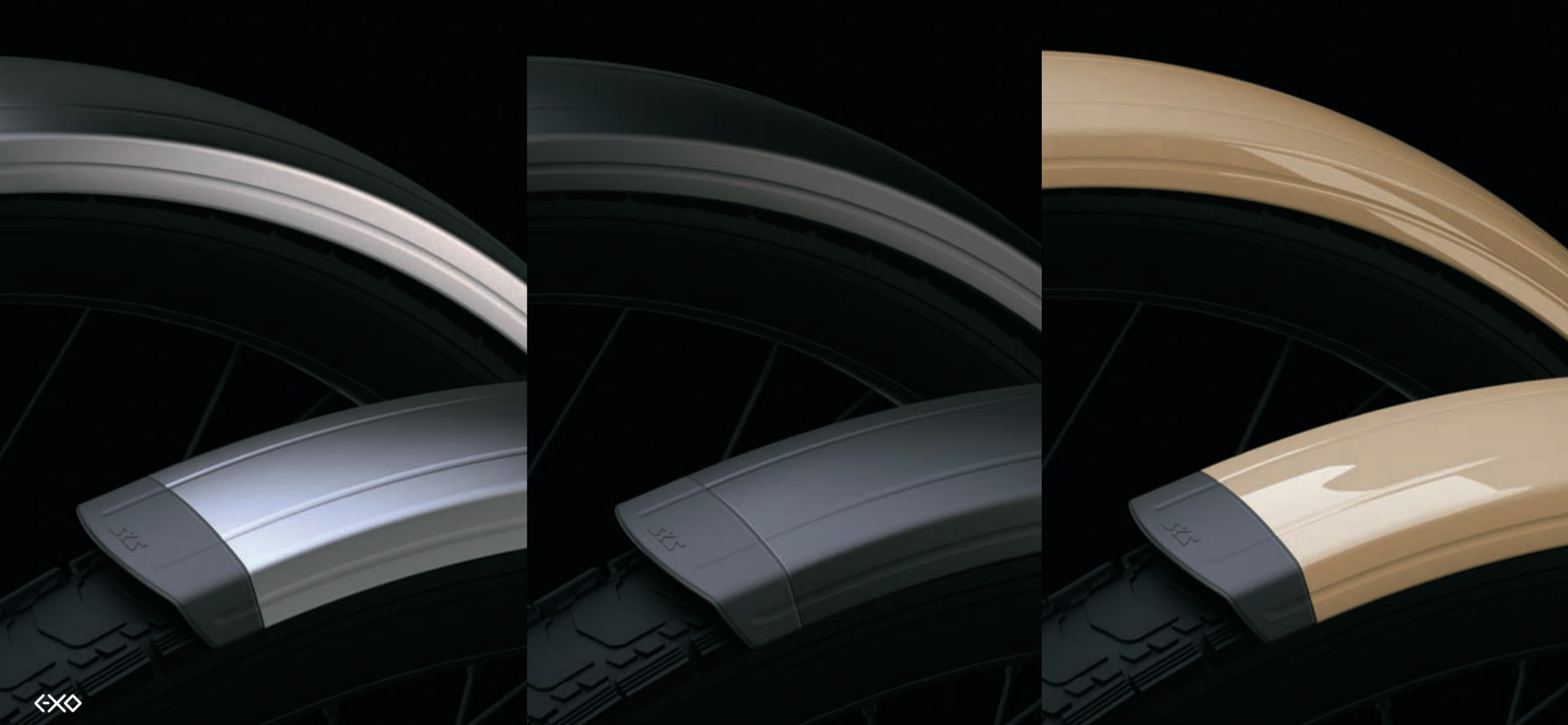

It is made from over 80% recycled and recyclable aluminum and is available in a variety of colors to meet the needs of the customer, as well as a robust and abrasion-resistant powder coating.

A sample of potential finishes (Credit: SKS)

A sample of potential finishes (Credit: SKS)

“Our finish is much nicer; we offer a mix of new design, German tech, full integration, and easiness of operation and assembly. We have advantages from every stage, from manufacturer to user,” said Zugno.

German-made

SKS has been set on bringing production back to Europe to help boost the area to “make it great again.” Especially now there’s increased interest in saving as much as possible and bringing production back closer to consumers. “We’ve been producing alloy fenders for a while now, made from a metal sheet that is bent and coiled, and this new one is really well made in Germany itself,” said Mr. Zugno.

SKS works together with their OE partners, designing specifications together, making drawings, and offering good prices. It takes a little time, they say, but after a sample has been accepted, they see a “perfect result on the bicycle.” For EU customers, SKS believes they offer a great brand with fantastic performance and price level.

“The clearance of warehouses may take longer than expected; it’ll have a deeper impact,” said Mr. Zugno. “Too many companies had made mistakes, and down the line, others have had to pay for that.”

“Plastic fenders are still our core business, and our chain guards are now also doing very well,” he added. “But now, a lot of our focus now goes into our new extruded aluminum fenders.”

SKS’s fender manufacturing techniques can be seen on their racks too—unlike many that would have welds holding them together. They are able to produce them in Germany at an acceptable price with a low MOQ, such as 120, which would not usually be possible. “Companies producing high-end bicycles who want maximum care for details can have a rack that perfectly matches their frame; others cannot offer this. We offer something different in a niche market,” said Mr. Zugno.

About 10 years ago, production could have been cheaper in Eastern Europe, but development time and costs have gradually increased. “We have developed a system that is very easy to assemble; our workers don’t need lots of training, and it’s effective with instant operation,” said Mr. Zugno.

The SKS team allocated to Taichung Bike Week 2025 (Mr. Zugno Center) (Pic: Ash Suter)

The SKS team allocated to Taichung Bike Week 2025 (Mr. Zugno Center) (Pic: Ash Suter)

The EXO is available from December 2025, with samples available before. The MOQ is 500 sets (1,000 mudguards). You can contact oem@sks-germany.com for more information.